News

Tim (our lead tech) wanted to push the red-line of his pump-gas, hydraulic-roller naturally-aspirated LS to 8,500 rpm and get more horsepower without losing low-end torque. He also wanted this to be a bolt-on project.

Like a lot of racers, this 408 cubic inch build started out powering his daily driver, a 2009 GMC Canyon. As time went on, he continued to invest into new go-fast parts and his truck slowly morphed from a daily driver that occasionally raced, into a race vehicle that could still be driven on the street. After competing in Drag Week 2018, he concluded that some some additional changes were needed to achieve his desired ETs and top speeds. His wish list was as follows:

- Increase red-line from 7,600 to 8,500 rpm

- Increase horsepower across the entire rpm band

- Maintain low-end torque

Adding 900 rpm to the red-line was for him and his truck, a particularly big deal. Shifting higher would allow him to hold first gear longer, drop into a sweeter portion of the power band with each shift and achieve a higher top speed. Given that neither Tim nor his truck are lightweights, bottom-end torque for launch could not be sacrificed. And of course, who doesn't want more horsepower?

Tim's foundation was and remains a GM 6.0L aluminum LS block with a Callies Compstar 4.000 inch stroke crank, Scat rods and Diamond r-series pistons. The top-end was comprised of BRE-ported LS3 heads with standard rockers and a Holley Sniper intake manifold/102 mm throttle body combination. When last on our dyno in early 2018, it pushed out a peak 767 hp at 7,000 rpm with power dropping sharply above 7,600 rpm. This was getting him down the track in 11.9 seconds with a top speed around 114 mph.

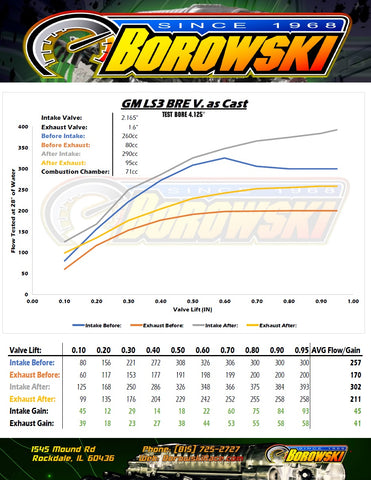

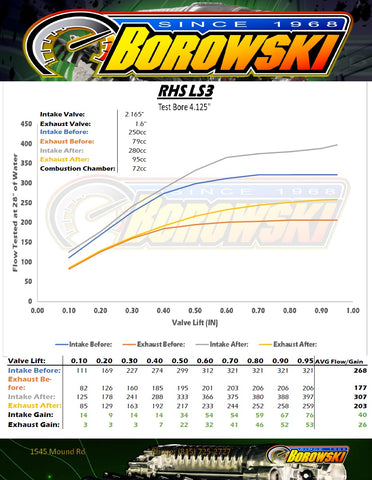

A big benefit of his being BRE's lead tech is that he is among the first to see new technology from our key vendors. In this case, credit goes to Bryan Pitcher who is our rep at COMP Cams. The first puzzle piece was COMP's new BSR shaft rocker set which was introduced at SEMA 2018. This affordably priced product offered a big jump in valve train strength and stability. When coupled with short-travel lifters, it could also extend the rpm range. In fact, Spintron testing at COMP's lab in Memphis had demonstrated stable performance as high as 10,000 rpm. Make no mistake however, just bolting on these rockers and dropping in the lifters won't get you there. The whole top end must work together to achieve these results. In any case, BRE quickly adopted the COMP BSR shaft rockers for their hydraulic-roller LS builds. Tim's hands-on experience building and dynoing these engines convinced him that he had to have a set under his own hood at some point. He knew all too well that the rest of the top-end needed to support his wish list. The next shoe to drop was when Bryan told Tim about the new RHS LS3 heads which are premium replacements for LS3 heads at a value-price. Tim immediately ordered a set and worked his porting magic on our 5-axis CNC. Comparing the CNC ported RHS to CNC ported LS3 heads, he wanted 12% more air flow at around the target valve lift. The 12% figure is the ratio of 8,500 to 7,600 rpm. The CNC ported RHS heads flowed 14% higher (380 vs. 366 cfm @ 0.70" lift) so Tim was now off to the proverbial races on his project.

In any case, BRE quickly adopted the COMP BSR shaft rockers for their hydraulic-roller LS builds. Tim's hands-on experience building and dynoing these engines convinced him that he had to have a set under his own hood at some point. He knew all too well that the rest of the top-end needed to support his wish list. The next shoe to drop was when Bryan told Tim about the new RHS LS3 heads which are premium replacements for LS3 heads at a value-price. Tim immediately ordered a set and worked his porting magic on our 5-axis CNC. Comparing the CNC ported RHS to CNC ported LS3 heads, he wanted 12% more air flow at around the target valve lift. The 12% figure is the ratio of 8,500 to 7,600 rpm. The CNC ported RHS heads flowed 14% higher (380 vs. 366 cfm @ 0.70" lift) so Tim was now off to the proverbial races on his project.

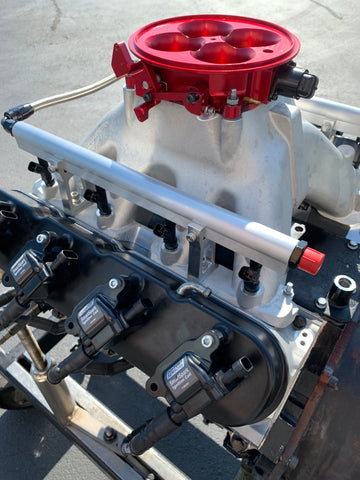

Tim's research had convinced him that CID's single plane intake manifold was best-in-class. It is designed for engine applications aiming to make 600+HP using LS3 cylinder heads. The CID Heads BE LS3 intake manifold has an overall height of 9.5" and features a square carb pad designed to suit a 4500 Dominator carburetor or throttle body. Its internal design features almost equal length runners and embodies the latest technology developed through extensive computer simulations and 3D modeling.

Working again with Bryan, Tim selected a FAST 2,000 cfm throttle body to mount on top of the CID intake manifold. The make-or-break selection however was the cam. Bryan and Tim went with a design for tight lash hydraulic lifters and lobes intended for high rpm capability. These features coupled with higher lift and duration were characterized by Bryan as "limited street'. Sounds like Drag Week to me.

Summary of Changes

| BEFORE | AFTER |

| Holley Sniper 102 mm t/b | FAST 2,000 cfm t/b |

| Holley Sniper intake | CID single plane intake |

| BRE ported GM LS3 heads | BRE ported RHS LS3 heads |

| Factory rockers arms | COMP BSR shaft rockers |

THE RESULTS

Tim sold his Sniper intake and throttle body to help pay for all his new parts so the original baseline is somewhat out of date. In addition, we had a drum of E98 fuel that needed to be emptied and Tim had the tune and injectors to handle it. Given access to free fuel, he chose to run all the current series of dynos on E98 except the first (pump gas) which verified comparable results. He then wanted to see how the elements worked separately so the dyno series was:

- CID intake/FAST throttle body, BRE CNC-ported GM LS3 heads, old cam;

- Add: BRE CNC-ported RHS LS3 heads, BSR shaft rockers;

- Add: new cam

Comparing old baseline to new baseline, the horsepower curves were an almost dead overlay other than being down about 2%. This difference is small enough to be within test error, real differences or both. The key finding was that the intake and throttle body by themselves neither changed the shape of the power curve nor raised the rpm range.

BRE CNC-Ported RHS LS3 Heads

Next step was swapping out the CNC ported GM LS3 heads with factory rockers for the CNC ported RHS heads with BSR shaft rockers. New ballgame! Peak horsepower jumped from 752 hp @ 6,900 rpm to 777 hp @ 7,100 rpm. Tim stayed into dyno pull longer and saw the engine was still pushing out 744 hp @ 8,200 rpm. The prize was in sight! Time to install the new cam.

Tim was committed to pushing the final dyno pull to his planned 8,500 shift point. The printout got to 8,400 rpm so he was close. The new cam pushed peak power to 791 hp which it held from 7,200 -7,400 rpm. It was still pushing out 769 hp at 8,400 rpm. As can be seen below, the overlay of the old baseline on the new chart shows no real difference in low-end torque but dramatic differences above 7,600 rpm.

Bottom Line: Tim met all his objectives and expects to be trimming a few tenths off his time slips. He plans on competing at Holley's LS Fest 2019 and should be spending time between races at the BRE canopy on Manufacturers Midway. If you are there, please come by to say hello, take a look at his truck and ask any questions you might have. In the meanwhile, check out the build video featuring both the dynos and time-lapse of the head changes.

BRE can offer any of the parts used in this build either individually or as complete kits depending upon your needs. We can also provide complete LS engines for whatever your needs may be. If interested, please call us at 815-725-2727.

Borowski Race Engines, Inc.

1545 Mound Rd Joliet, IL 60436

www.borowskirace.com

Reference Data:

1. Air flow data GM LS3 heads (w & w/o BRE CNC work)

2. Air flow data RHS LS3 heads (w & w/o BRE CNC work)

Product Types

Product Vendors

- Aeromotive

- Airflow Research

- All Pro Cylinder Heads

- ARP

- Borowski Race Engines

- Brodix

- BullsEye Power

- Callies

- CID

- Comp Cams

- Dailey Engineering

- Dart

- Daytona Sensor

- Diamond Pistons

- Emtron

- Energy Mfg

- FAST

- FuelTech

- GM

- Holley

- Hooker Headers

- Hughes Performance

- Manley

- Manton Pushrods

- Maxima Racing Oils

- Melling

- Moroso

- MSD Ignition

- ProCharger

- RacePak

- RHS

- Stef's Performance

- Trend

- Whipple

- View More View Less